What Are the Uses of Ceramic Fiber Ropes? A Comprehensive Guide for Industrial Applications

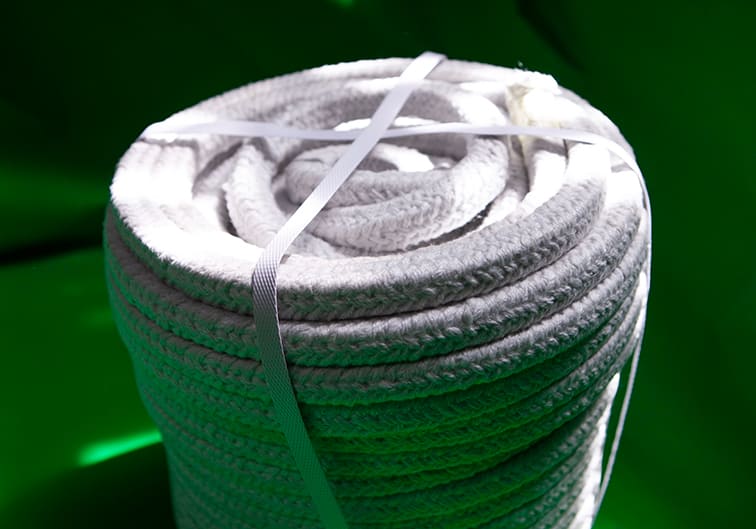

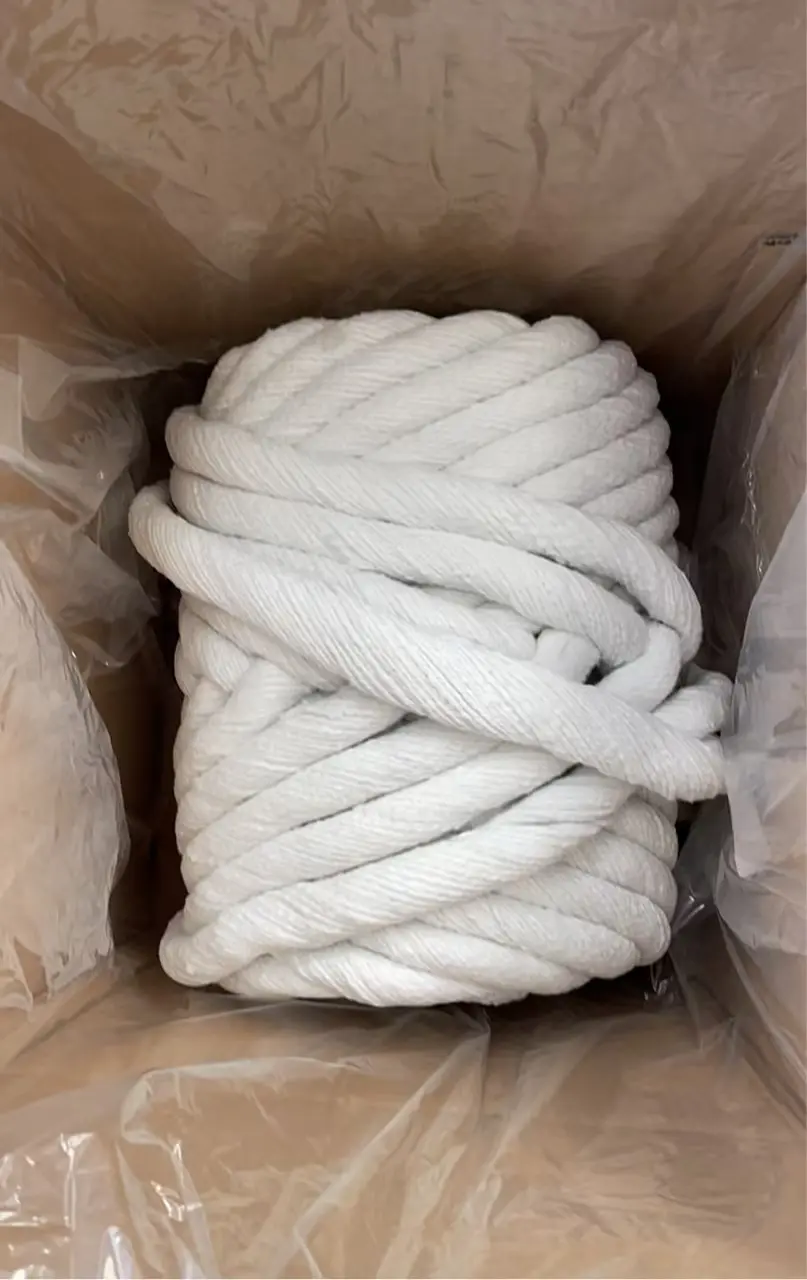

Ceramic fiber ropes, renowned for their exceptional heat resistance and durability, have become indispensable in high-temperature industrial environments. These versatile materials are engineered to withstand extreme conditions, making them ideal for a wide range of applications. Below, we explore the primary uses of ceramic fiber ropes and why they are preferred over traditional alternatives like asbestos.

1. High-Temperature Insulation in Kilns and Furnaces

Ceramic fiber ropes are extensively used to seal gaps in kilns, boilers, and industrial furnaces. Their ability to resist temperatures up to 1,260°C (2,300°F) ensures minimal heat loss, improving energy efficiency and reducing operational costs. Key applications include:

- Door and hatch seals: Preventing heat escape in ceramic kilns and metal smelting furnaces.

- Expansion joints: Absorbing thermal expansion in heat treatment equipment.

- Pipe and duct insulation: Wrapping pipelines carrying hot gases or molten metals.

2. Petrochemical and Refinery Applications

In petrochemical plants, ceramic fiber ropes play a critical role in:

- Flue gas sealing: Blocking leaks in reformer tubes and catalytic crackers.

- Reactor insulation: Protecting equipment from corrosive chemicals and high temperatures.

- Fireproof barriers: Installing as passive fire protection in LPG storage areas.

3. Marine and Offshore Industry

Ceramic fiber ropes are favored in marine environments due to their resistance to saltwater corrosion and fire. Applications include:

- Engine room insulation: Sealing exhaust systems and turbines.

- Cable and pipe penetrations: Preventing fire spread on ships and offshore platforms.

4. Aerospace and Automotive Testing

In high-speed testing chambers, ceramic fiber ropes are used to:

- Isolate thermal zones: Separating heated components from sensitive electronics.

- Protect test equipment: Withstanding repeated thermal cycling during engine testing.

5. Metallurgy and Foundry Operations

Metal foundries rely on ceramic fiber ropes for:

- Ladle and tundish seals: Containing molten metal during casting.

- Crucible insulation: Reducing energy consumption in metal melting furnaces.

6. Power Generation

Thermal power plants use ceramic fiber ropes for:

- Boiler door seals: Maintaining combustion efficiency.

- Turbine insulation: Protecting casings from extreme heat.

7. Fireproofing and Safety

Beyond industrial settings, ceramic fiber ropes are used in:

- Fire curtains: Partitioning buildings during emergencies.

- Welding blankets: Shielding workers from sparks and UV radiation.

Why Choose Ceramic Fiber Ropes Over Asbestos?

- Safety: Asbestos-free and non-carcinogenic.

- Performance: Higher thermal stability and lower thermal conductivity.

- Durability: Resistant to chemical attack and thermal shock.

FAQs About Ceramic Fiber Ropes

Q: Can ceramic fiber ropes withstand molten metal?

A: Yes, versions reinforced with stainless steel wires resist splashes from aluminum, zinc, and steel.

Q: How long do ceramic fiber ropes last?

A: Typically 5–10 years in continuous use, depending on temperature and environment.

Q: Are they easy to install?

A: Yes, their flexibility allows for wrapping, braiding, or packing into irregular gaps.

Q: Do they require maintenance?

A: Minimal—periodic inspection for fraying or compression is recommended.

Conclusion

Ceramic fiber ropes are a cornerstone of modern industrial safety and efficiency. Their adaptability to extreme conditions, combined with eco-friendly compositions, makes them a superior choice over legacy materials. Whether sealing a furnace, protecting offshore equipment, or enhancing power plant efficiency, these ropes deliver unmatched performance.

Comments

Post a Comment